http://inhabitat.com/the-worlds-first-3-d-printed-violin-sounds-like-the-real-thing/

The world’s first 3D-printed violin sounds like the real thing

wood bridge, metal tuning pegs

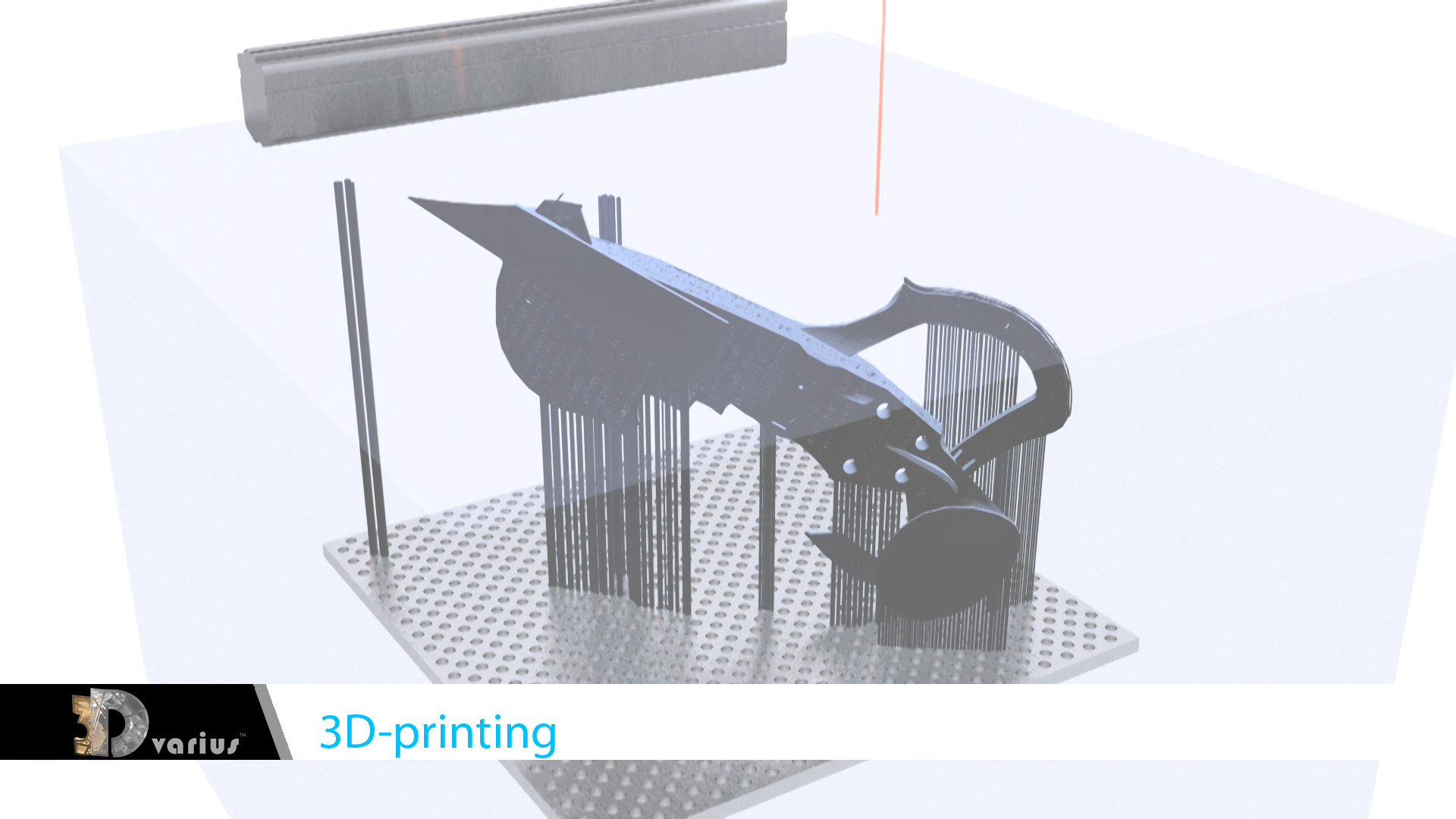

3D-PRINTING

Our choice of 3d-printing technology is stereolithography* because of its exceptional printing definition and the resistance of its printed objects.

*Stereolithography is a 3D printing technology used for producing models, prototypes, patterns, and production parts up one layer at a time by curing a photo-reactive resin with a UV laser or another similar power source.

*Stereolithography is a 3D printing technology used for producing models, prototypes, patterns, and production parts up one layer at a time by curing a photo-reactive resin with a UV laser or another similar power source.

POST-PRINTING TREATMENT: DEBURRING

At this stage, all the excess resin from the printing stage is manually removed. Then precision tools are used to perfectly complete this phase.

POST-PRINTING TREATMENT: CLEANING AND BLOWING

The body of the instrument is cleaned with a cleaning solution and high pressure blowing.

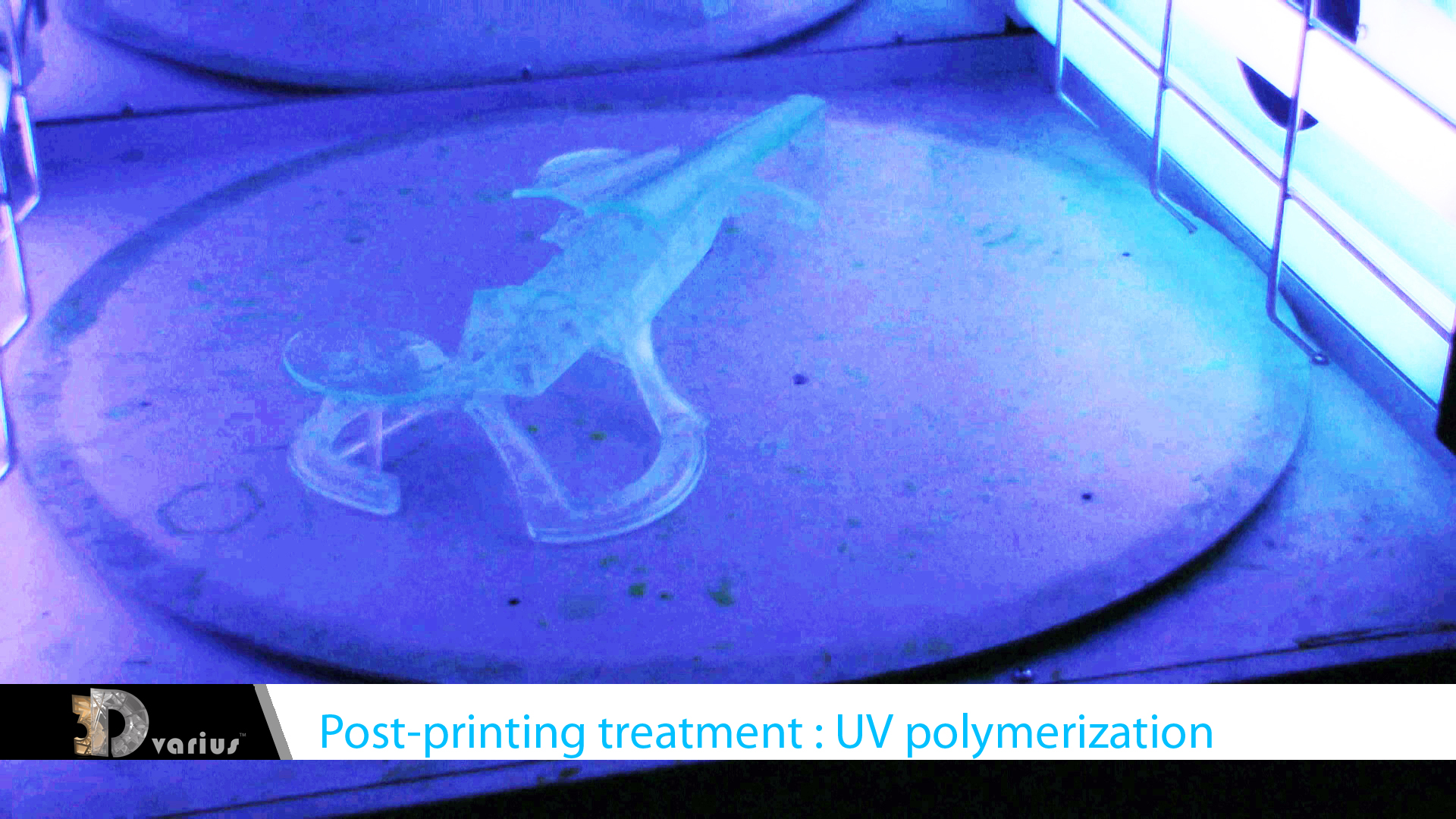

POST-PRINTING TREATMENT: UV POLYMERIZATION

This step aims to protect the instrument from external harm by completely polymerizing the violin’s structure.

SURFACE TREATMENT

Surfaces in contact with the strings and the musician’s body are sanded with extreme precision to ensure sound purity and offer optimal playing comfort.

FINAL ASSEMBLY

This is the most delicate step, as it is the first time when the structure of the violin is subjected to actual string pressure. The stringing and tuning must be done progressively and be perfectly symmetrical to attain the perfect chord.

No comments:

Post a Comment